In factories, power plants, and other industrial environments, Operational Technology (OT) networks are the beating heart of functional processes. These networks control machinery, monitor safety processes, and ensure that everything continues to operate safely and efficiently. But while IT networks have benefited from advanced monitoring tools for years, outdated OT networks often lag behind. Our devices help ensure these networks comply with current standards and guidelines.

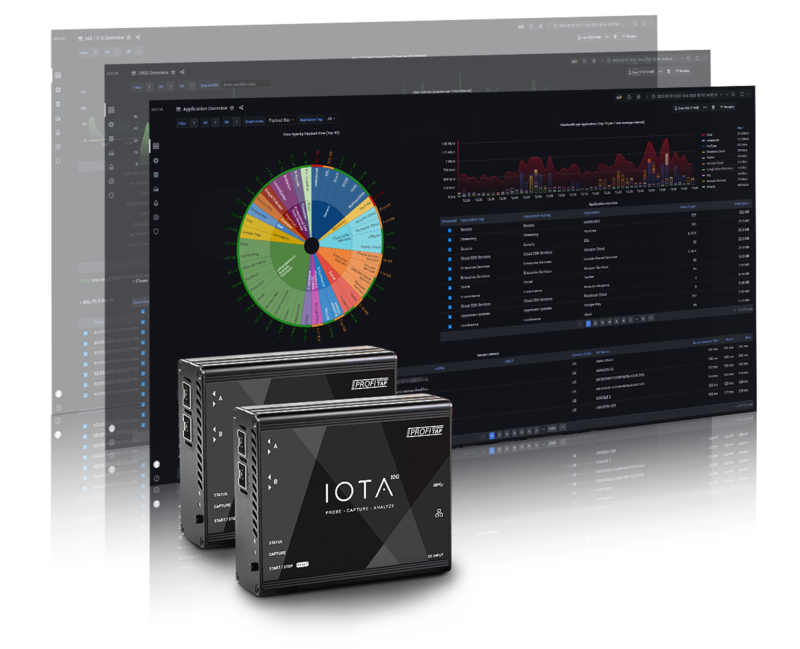

IOTA offers a powerful and specialized solution that enables accurate, real-time analysis of OT network traffic without disrupting critical processes. IOTA thus ushers in a new era of smart, secure, and future-proof industrial monitoring and automation.

Why Traditional Tools Fall Short

OT networks are fundamentally different from their IT counterparts. While IT revolves around data traffic, users, and applications, OT focuses on real-time control and monitoring of physical processes. Consider, for example, an assembly line that needs to be synchronized down to the millisecond, or temperature controllers in chemical plants. These systems utilize specialized protocols such as PROFINET, Sercos III, and Modbus.

The demands are extremely high: minimal latency, maximum reliability, and no room for error. A single lost packet of data can shut down an entire production line. This means that traditional IT analysis tools are inadequate in this context. They lack the timing precision and protocol knowledge needed to gain insight into industrial processes. data communication.

IOTA: tailored monitoring for OT

The IOTA is specifically designed for monitoring industrial networks. With features such as hardware timestamping accurate to 8 nanoseconds, support for in-line and out-of-band capturing, and a capture rate of up to 3.2 Gbps, the IOTA offers everything needed for accurate analysis.

Combined with Network TAPs, which passively intercept traffic without affecting the data flow, IOTA provides network operators with a clear, real-time view of their entire OT network. This makes it easier to detect outages early, analyze threats, or simply optimize overall performance.

|

|

|

|

IOTA EDGE |

IOTA CORE |

|

Ideal for SMBs. Inline or out-of-band capture at 3.2 Gbps and hardware timestamping with 8-nanosecond accuracy. |

Designed for larger networks. Out-of-band capture at speeds up to 100 Gbps and supports multiple high-speed interfaces. |

Strategy for maximum network visibility

To get the most out of IOTA, you need to be smart and purposeful. It's crucial to adopt a strategic approach that aligns well with the OT environment.

- Place TAPs at key locations in the OT network, for example, before and after critical devices. These passive measurement points read all network traffic, both incoming and outgoing, without disrupting network operation. This gives you complete insight into what's happening without interrupting the process itself.

- Use IOTA to monitor and analyze network traffic in real time. Network traffic data (PCAP files) can also be stored on the internal SSD for later inspection. Network administrators always have a complete picture and can easily detect hardware degradation, bottlenecks, or defective components.

- Use IOTA's precise timestamping (down to the nanosecond) and comprehensive integrated analysis dashboards to analyze the Modbus industrial Ethernet protocol.

The benefits of IOTA in OT

By implementing IOTA you will benefit from:

- Non-intrusive, full network visibility.

- Maintaining network performance and continuity without delay.

- Enhanced security through passive monitoring.

- Real-time insights with protocol-specific dashboards.

- Communication storage on internal SSD for later analysis.

IOTA integrates easily with existing systems and enables the integration of new technologies, bridging the gap between legacy OT systems and modern implementations. As companies modernize, our tools become indispensable for ensuring the reliability, efficiency, and security of OT networks.