Spring-loaded toothed brake versus conventional permanent magnetic brake

Powerful spring-loaded toothed brake as an alternative to conventional permanent magnet brakes

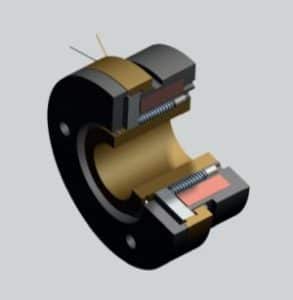

Safety component with “teeth”.

The rapidly growing robotics market, but also other demanding industries, require drive components with ever higher power densities and safety functions. In order to meet these challenges in a targeted manner, the Mönninghoff machine factory offers a particularly space-saving yet very powerful spring-loaded toothed brake as the perfect alternative to conventional permanent magnet brakes.

Wherever friction brakes offer high positioning accuracy, but quickly reach their limits due to the friction torque transmission, the toothed brake from Maschinenfabrik Mönninghoff GmbH & Co. KG, Bochum can be used. New production processes ensure a gear transmission that can position and fix the brake in very fine steps. The positive torque transmission offers significantly higher torques in the range of up to 6000 Nm. Especially in the field of robotics or servo technology, these brakes are increasingly used with their small space requirements, their high power density and their maximum safety requirements.

Function and structure

In normal operation, the spring-loaded toothed brake is kept closed when it is de-energized by the compression springs that engage the two toothed rings. The torque is transmitted via the guide teeth with little play and without slippage. The brake is opened by means of an electromagnet that counteracts the spring force and thus releases the brake. This allows the brake to function as a Fail-Safe product. In all its functions, this spring-loaded toothed brake can also be designed as a clutch.

The right brake for every need

The Mönninghoff engineering company develops a wide range of couplings and brakes for the special requirements of every industry and every application. For example, the brake can be released pneumatically or actuated electrically. It is also conceivable to set them with a defined spring force. In addition, the individual design of the gear geometry ensures that every special application can be treated with a special solution. There is also the possibility of making the brake “bistable”. This means that the most recent switching state is guaranteed to be retained in the event of a power failure. This bistable variant is particularly well received in mobile applications, because energy is only required to change the switching state and is therefore very energy-efficient.

View the Mönninghoff brochure about the very powerful spring-loaded toothed brake here.

For more information: info@eltrex-motion.com