SkelGrid 2.0: Flexible, Scalable, and Easy-to-Maintain with Integrated Master Controller and Modular Switchgear by Skeleton

SkelGrid 2.0 is an innovative energy storage system designed by Skeleton to meet various needs. This technical post delves into its core components, highlighting the user-friendly design, robust safety mechanisms, and advanced monitoring capabilities. A closer look at two technical features—master controller and modular switchgear—reveals their significant roles in the system's functionality.

Ease of maintenance is a key feature of SkelGrid 2.0, designed with a user-friendly approach to ensure reliability and longevity. Its plug-and-play design eliminates the need for software installation or configuration. Upon integration, the energy storage modules are automatically detected and configured by the master controller, streamlining the setup process.

Maintenance is further simplified through the use of State of Health (SOH) monitoring, which provides estimations on the current degradation and remaining life of the modules. This functionality is crucial for planning preventive maintenance, allowing for timely interventions that extend the system's operational lifespan, as all energy storage technologies lose performance over time. SOH-based balancing utilizes algorithms to equalize module aging. This approach ensures that all modules operate efficiently and reduces the likelihood of premature wear, contributing to the system's overall reliability and performance.

The system meets IEC overvoltage category (OVC) III, enhancing its ability to withstand voltage spikes and surges originating from the grid. This feature not only protects the system but also contributes to its stable performance under varying electrical conditions.

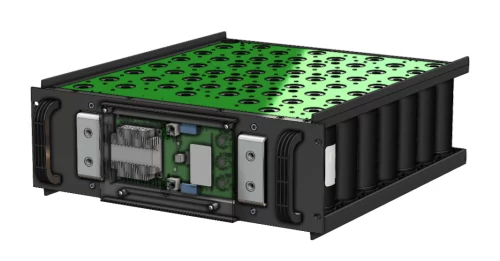

The supercapacitor modules are the cornerstone of the SkelGrid system, engineered for unparallel capacity and power output. These modules distinguish themselves from previous generations by offering a +77% increase in energy density and power output, setting a new industry standard for footprint optimization and performance.

Master Controller

Within SkelGrid 2.0, the master controller operates as the central intelligence unit, orchestrating the system's operations, monitoring the status of modules and optimizing performance. It communicates internally with the supercapacitor modules using Iso SPI (Isolated Serial Peripheral Interface). For external communications, the master controller utilizes CAN2B with the J1939 protocol.

Features:

- Cell Balancing: The controller is key for maintaining even performance across supercapacitors, addressing overcharging risks and optimizing energy handling. It operates controlled resistive balancing (sometimes called “active”) at both cell and rack levels, for minimum maintenance and maximized longevity.

- State of Health Monitoring: It offers detailed health and operational status for each cell, enabling maintenance based on condition to avoid failures and ensure consistent operation. The system prioritizes SOH information, monitors cell temperatures, keeps performance records and provides inputs for the advanced balancing algorithm.

- Integration and Accessibility: The controller facilitates the integration of SkelGrid with existing energy systems via a CAN port, easing the access and management of operational data. This feature is crucial for developing energy management strategies that suit various applications.

- Safety and Fault Detection: Includes safety logics to disconnect from the grid during overcurrent, overtemperature, and overvoltage situations. It also identifies sensor failures and potential issues with the controller itself, which is vital for maintaining system reliability. It also features an error injection capability, to test the functionality and effectiveness of higher-level control systems.

- Communication: Capable of outbound communication as well as inbound. It relays the state of function, requests internal operation data, and alerts to overvoltage, overcurrent, and overtemperature conditions, ensuring the system's operational integrity.

- Scalability: A single master controller can accommodate up to 10 supercapacitor modules. Furthermore, each CAN loop has the capacity to host up to 10 master controllers, enabling the connection of up to 100 modules to a single PLC.

Modular Switchgear

SkelGrid 2.0 offers an optional modular switchgear for enhancing the system's safety and selectivity. This switchgear incorporates an isolation switch, contactors for thermal overload protection, fuses for overcurrent protection, and built-in discharge contactors, providing a comprehensive suite of protections against electrical faults while maximizing flexibility of the overall energy storage system.

To accommodate the diverse needs of end customers, there is a large variety of switchgear options available, designed to meet different voltage and current requirements. This ensures that SkelGrid can be precisely tailored to specific operational demands. Additionally, the switchgear offers operational versatility; it can be controlled either by the master controller or by a customer's PLC. The modular design of the switchgear not only facilitates easy integration and scalability but also enables SkelGrid to meet the evolving safety and performance standards required by modern energy storage applications.

Features:

- Space Efficiency: The switchgear's compact design (19-inch rack compatible 4U height) is particularly beneficial in energy storage installations where space is at a premium. Its efficient layout allows for the inclusion of comprehensive safety mechanisms without sacrificing system footprint or accessibility.

- Safety and Protection: The switchgear is equipped with fuses and contactors for the main DC lines and a manual isolation switch for maintenance, designed to protect against electrical faults and prevent operational interruptions by allowing selective disconnection of SkelGrid units from the main busbar (in case of maintenance on one or more units). The exact configuration of these components can be tailored based on the customer's power and availability needs.

- Operational Control: Integration with the master controller allows for a harmonized operation, where safety mechanisms are continuously monitored and managed. This ensures smooth operation and a swift response to any anomalies.

- Charging and Discharging Flexibility: An external resistor can be added by the customer to enable automatic pre-charge and discharge operations, conducted in cooperation between the master controller and the switchgear. Additionally, an optional portable charging and discharging unit is available.

- Support Systems: The switchgear includes a 24VDC power supply unit (fed with 120/230Vac) to power actuators, modules and master controller. Control terminals are accessible for customer PLC integration, offering customization through direct control.

- Adaptable Connections: The switchgear's connection interfaces to the DC bus are bolted terminals, with a standard configuration that allows for connection from the top of the cabinet. Optionally, the cabinet can be upgraded to support connection from the bottom, enhancing installation flexibility based on site-specific requirements.

If you have any question or if you want additional information, please contact Nijkerk Electronics!