TU Delft is enhancing real-time HVDC simulation with Machine Learning in RSCAD FX

About TU Delft and RTDS

An advanced university laboratory housing one of the largest real-time simulators in Europe

Delft University of Technology (TU Delft), located in Delft, Netherlands, first adopted the RTDS® Simulator in 2004. In the years since, TU Delft has gradually upgraded and expanded their real-time simulation laboratory. Today, in the Electrical Sustainable Power (ESP) Lab, they own and operate one of the largest RTDS Simulators in Europe, which they use to simulate the Dutch power system and comprehensively test technologies for a secure energy transition.

TU Delft has expertise in HVDC simulation and testing, with a particular focus on modelling MMC-HVDC systems. Among the university’s many pursuits is the InterOPERA project, funded by Horizon Europe, in which they collaborate with twenty European partners on enabling the interoperability of multi-vendor HVDC grids. Their RTDS Simulator laboratory will be indispensable for testing multi-vendor HVDC controls under the project.

PROJECT FOCUS

APPLYING NEURAL NETWORKS IN RSCAD® FX FOR ADAPTIVE MMC-HVDC CONTROL

Here it’s applied for MMC-HVDC control, but it can theoretically be used for any application, as the loss function is a user-defined input to the model.

The complexity of control in MMC-HVDC systems presents a challenge for power systems engineers. TU Delft was interested in exploring the integration of neural networks and machine learning into the control architecture of MMCs, with the goal of enhancing and optimizing MMC scheme control. They leveraged the RTDS Simulator for modelling, neural network training, and demonstrating the concept.

Researchers at TU Delft introduced a data-driven, model-free machine learning approach for predictive control of an MMC scheme modelled on the RTDS Simulator. Artificial and long short-term memory neural networks (ANNs and LSTMs) were modeled in RSCAD FX and trained with data from the real-time simulation.

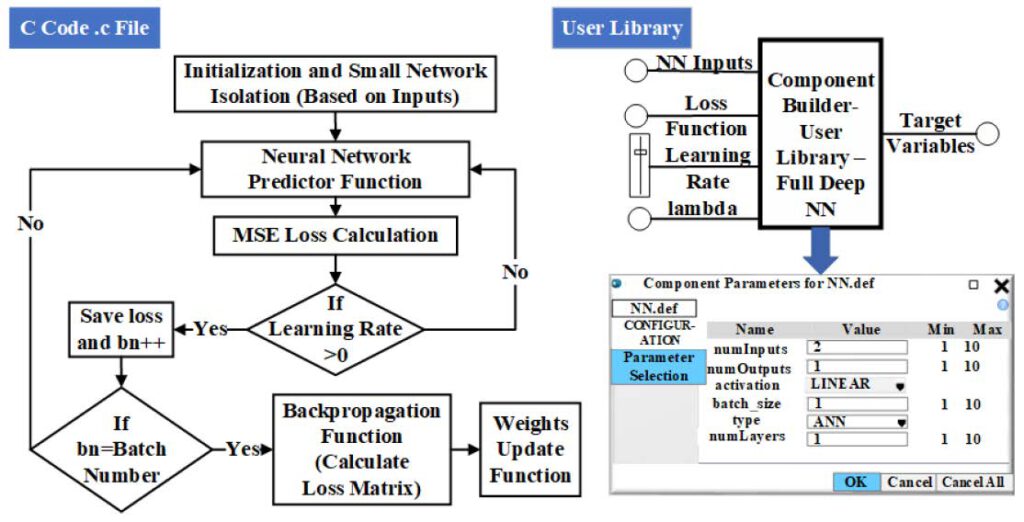

A simplified look at the neural network’s logic and implementation in RSCAD FX – Image courtesy of TU Delft

Both online (real-time) and offline processes were used to reduce computational time and complexity. A Python script was developed to parse simulation data and train the offline neural network model in order to generate weight and bias matrices which were then manually inserted into the online neural network component.

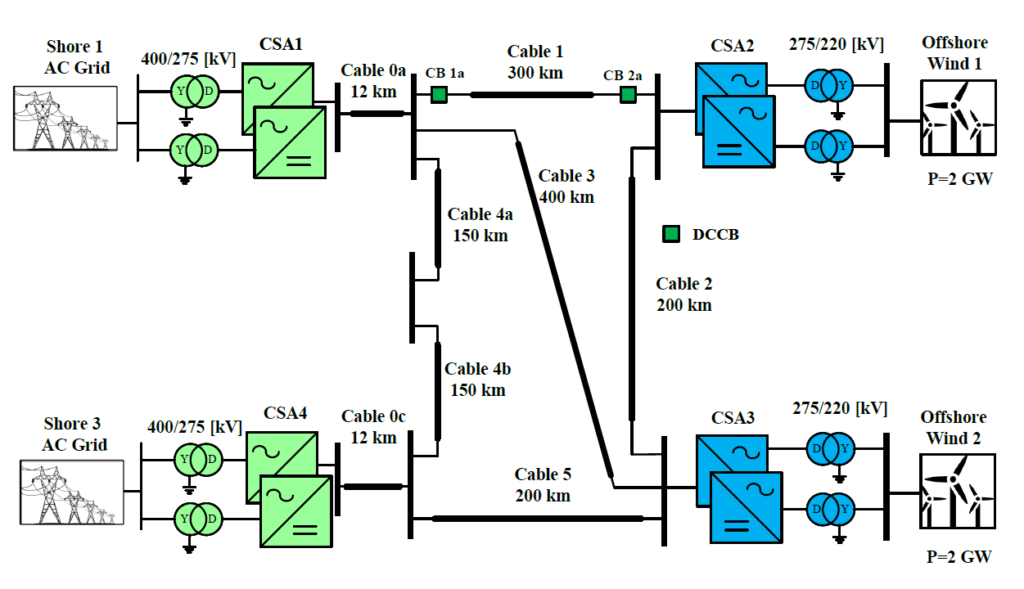

To investigate the effectiveness of the neural network control techniques, a four-terminal MMC-based HVDC power system was simulated, representing two offshore wind farms (grid-forming control) and two onshore grid-connected converters. One onshore converter maintains the DC voltage of the system via conventional PI control, and the other is used for active power control via the neural network approach.

A simplified look at the neural network’s logic and implementation in RSCAD FXImage courtesy of TU Delft

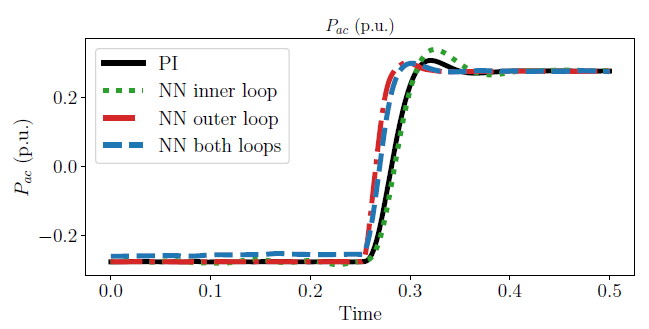

Simulation results showed enhanced precision and speed of submodule capacitor voltage balancing, and successful prediction of submodule triggering sequence via neural networks. The method yields faster and more robust control with reduced complexity – a solution for managing MMCs more efficiently and reliably.

Project Outcomes

OPENING THE DOOR FOR WIDER MACHINE LEARNING APPLICATIONS

TU Delft’s work has successfully demonstrated secure and resilient machine learning control techniques in the real-time simulation environment. A wide variety of test cases was run, validating the stability of the approach in even large-scale, high-power cases.

The combined use of online and offline training presents a unique and efficient approach to multi-layer neural network implementation in the real-time environment. TU Delft’s work has yielded a toolbox for neural network / machine learning-based adaptive control in the RSCAD FX environment which can be used for other applications, opening the door for many future possibilities for using neural networks with the RTDS Simulator.

The results of applying neural networks to inner and outer loop control, compared to traditional PI control – Image courtesy of TU Delft